Hi, I'm Elizabeth (Maylin) Rawson, the 2023-2024 Aeroshell lead. I made this article based on my own experience as lead conducting and managing the composite manufacturing of Daybreak (2022-2024). This document is primarily for aeroshell management to understand how to choose and acquire materials in preparation for a layup. This is also helpful for aeroshell members who want to understand more about the materials that we use.

To the future aeroshell leads: I hope you got good donations in the composites departmenttry to ensure you get as many donations as possible. Composites are very expensive; while I was a lead, I spent roughly $17000 in 2023-2024 (very few donations). Please beg work with your operations lead in advance to acquire as many materials as they can so Solar doesn't go broke.

My favorite places to buy materials, especially fabrics, are Composite Envisions and Fiberglast. As of the time I'm writing this I know that we have a 20% discount code from Fiberglast. However, I actually prefer Composite Envisions because you can buy basically everything you need there which means that you can order in bulk. Additionally, their clearance section is better. If you buy from their 2nd quality fabrics, their fibers can get really cheap and rival Fiberglast.

...

| Fiber | Uses | Pros | Cons |

|---|---|---|---|

| Carbon fiber | Used for the exterior of the car |

|

|

| Fiberglass | Typically used for making molds |

|

|

| Kevlar | Required in the canopy by regulations |

|

|

Tow: A bundle of fiber that is identified by the number of carbon filaments they contain. Each "k" stands for a thousand fibers.

| Tow | ||

|---|---|---|

| 1k | ||

| 3k | ||

| 6k | ||

| 12k | ||

Weave: the way the fibers are bundled together

- Fabric stability: ability for a fabric to maintain its weave angle and fiber orientation

- The higher stability a fabric has, the lower the formability

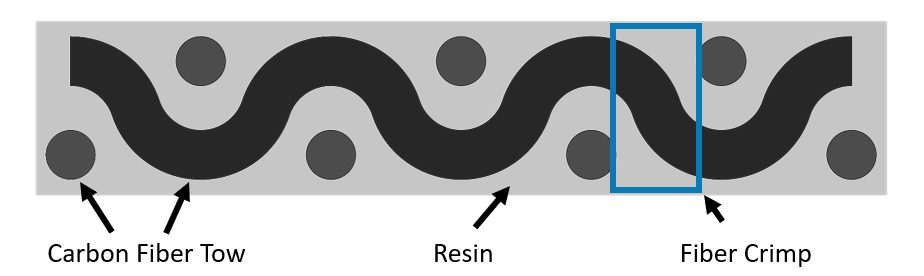

- Crimp: the curvature of a fabric in a single weave

- A very tight weave will make the crimp (curve) become more tight.

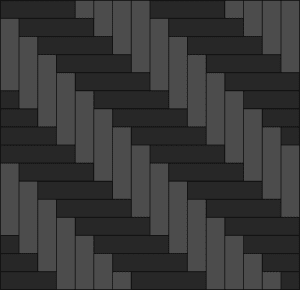

| Weave | Appearance | Definition | Uses | Pros | Cons |

|---|---|---|---|---|---|

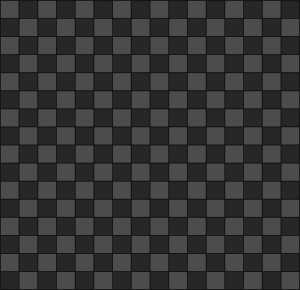

| Plain weave | This is one of the most common types of weaves for carbon fiber. A tow strand in plain weave passes over 1 tow and under 1 tow. |

|

|

| |

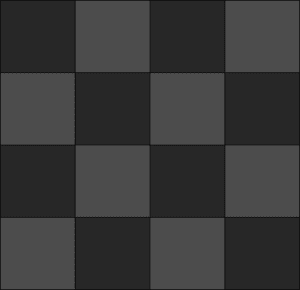

| Plain weave (spread tow) |

| Like your |

| regular plainweave, but the filaments are spread into a wider tow. |

|

|

| ||

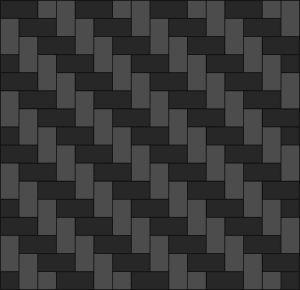

| Twill weave (2x2) | This is one of the most common types of weaves for carbon fiber. If you follow a tow strand in a twill weave it passes over a set number of tows and then under the same number of tows. Since this is 2x2 twill weave, it passes over 2 tows and under 2 tows. There is a longer distance between tow interlaces which means fewer crimps. |

|

|

| |

| Twill weave (3x3, 4x4, etc) |

Twill weave with less formability than standard 2x2 twill weave. The weave is less tight than 2x2 twill. We have historically rarely/never used this, but if you need to make a composite with many complex, tight curves then you may want to consider this. There is an even longer distance between tow interlaces which means fewer crimps than regular twill weave |

Tow

|

|

Density

Fabric orientation

...

Leads, encourage your facilities lead beforehand to buy protective gear. This way three teams don't have to buy stuff, rather OB buys stuff.

Step-by-step guide

| Info |

|---|

References: |

Related articles

| Filter by label (Content by label) | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

...