...

| Fiber | Uses | Pros | Cons |

|---|---|---|---|

| Carbon fiber | Used for the exterior of the car |

|

|

| Fiberglass | Typically used for making molds |

|

|

| Kevlar | Required in the canopy by regulations |

|

|

Tow: A bundle of fiber that is identified by the number of carbon filaments they contain. Each "k" stands for a thousand fibers.

| Tow | ||

|---|---|---|

| 1k | ||

| 3k | ||

| 6k | ||

| 12k | ||

Weave: the way the fibers are bundled together

- Fabric stability: ability for a fabric to maintain its weave angle and fiber orientation

- The higher stability a fabric has, the lower the formability

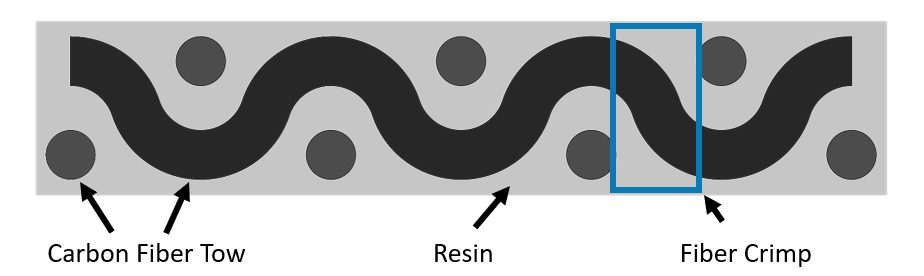

- Crimp: the curvature of a fabric in a single weave

- A very tight weave will make the crimp (curve) become more tight.

| Weave | Appearance | Definition | Uses | Pros | Cons |

|---|---|---|---|---|---|

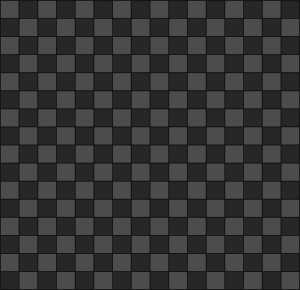

| Plain weave |

This is one of the most common types of weaves for carbon fiber. A tow strand in plain weave passes over 1 tow and under 1 tow. |

|

|

| |

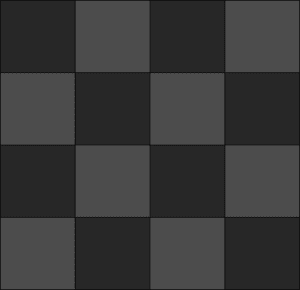

| Plain weave (spread tow) | Like your regular plainweave, |

- Flat sheets

- Tubes

- Bulkheads

- Panels

| but the filaments are spread into a wider tow. |

|

|

| ||

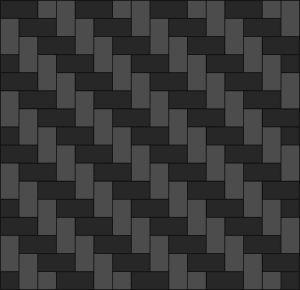

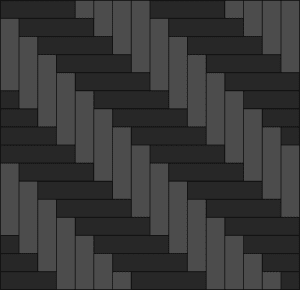

| Twill weave (2x2) | This is one of the most common types of weaves for carbon fiber. If you follow a tow strand in a twill weave it passes over a set number of tows and then under the same number of tows. Since this is 2x2 twill weave, it passes over 2 tows and under 2 tows. There is a longer distance between tow interlaces which means fewer crimps. |

|

|

| |

| Twill weave (3x3, 4x4, etc) | Twill weave with less formability than standard 2x2 twill weave. The weave is less tight than 2x2 twill. We have historically rarely/never used this, but if you need to make a composite with many complex, tight curves then you may want to consider this. There is an even longer distance between tow interlaces which means fewer crimps than regular twill weave |

|

|

Tow: A bundle of fiber that is identified by the number of carbon filaments they contain. Each "k" stands for a thousand fibers.

Density

Fabric orientation

...