Mechanical Procurement

Composites

Layup

- Carbon Fiber (WIP)

- Weave: Twill

- Density: 2x2

- Peel Ply

- Purpose: Peel ply is the layer placed in between our composite fabric and all the bagging material. The purpose it to have an easily removable layer that can be pealed off once the resin has set. This helps ensure that nothing binds the surface of the composite and acts as a separation layer between all our bagging material and composites.

- Requirements:

- Size: Minimum 1 yard in width

- Length: As long as we can get. Typically use about 120ft per solar car at a minimum

- Max Temp: 250F (At least for our 2023 resins)

- Notes: Generally we don't have a lot of requirements for this. Most will do for our current wet layup application. If we go for resin infusion there are a few more requirements but I will list them in that section.

- Breather

- Purpose: This layer acts as a spacer layer for air to be able to move through thus allowing there to be an even vacuum to be pulled across the whole mold.

- Requirements:

- Size: Minimum 1 yard in width

- Length: As long as we can get. Typically use about 120ft per solar car at a minimum

- Notes: This one again is pretty much anything that will do that is called breather. There are not a lot of differences between different options until you get to resin infusion

- Vacuum Bag

- Purpose: This is the material that forms the "bag" around the composite so that it can effectively put an even pressure across the whole composite.

- Requirements:

- Size: Minimum 1 yard in width

- Length: As long as we can get. Typically use about 120ft per solar car at a minimum

- Elongation: 200%

- Tensile Strength: 3100psi

- Notes: Elongation and tensile strength are not hard numbers. If it's below just talk to the aero team to see if it will still work

- Tacky Tape

- Purpose: This is the tape that seals the vacuum bag. Its basically the sealant for all air gaps in the mold and is the only thing stopping air from getting into the molds

- Requirements:

- IT MUST BE YELLOW THERE IS A BIG DIFFERENCE

- Type of tacky tape: Yellow, this is one of the stronger holding tacky tape. If we can get stronger tacky tape that will also do but it has to be at a bare minimum the yellow variety

- I'll make sure to put in an actual holding number later if there i sone

- Length: As long as ppl are willing to give. I believe on average we use something like 200ft per year

- Notes: Tacky tape plays one of the biggest roles for our car as it is the difference between pulling a vacuum and not so getting the correct strength is integral to our success

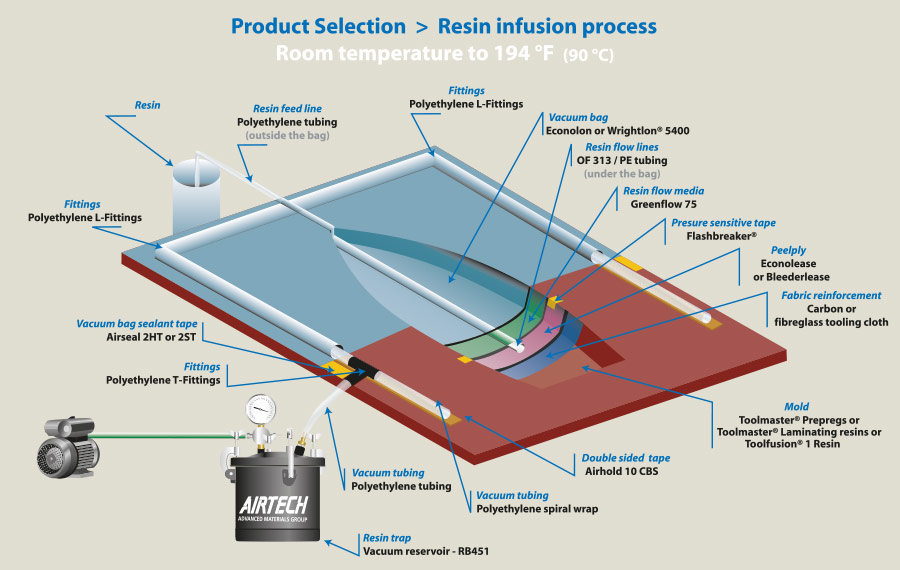

Resin Infusion

https://www.calameo.com/read/006348093196099acfcf7?page=3

- Flow Media

- Purpose: Flow media is like breather but instead of being a kind of fluff it is a thin sheet of fishnet-like nylon. The reason for this is so that it is able to aid in the resin distribution instead of just being used for pulling an even vacuum.

- Requirement:

- Notes:

- Vacuum Tubing

- Purpose:

- Requirement:

- Notes:

- Spiral Tubing

- Purpose:

- Requirement:

- Notes:

- Resin Break/Filter Jacket

- Purpose:

- Requirement:

- Notes:

Dynamics

WaterJet

- Purpose:

- Requirement:

- Notes:

Power Generation

Solar Panels

Maxion Gen 3 & Gen7 or Gen 5 & Gen 6 (Pref 3 & 7)

- Purpose: They are the solar cells for the car so they are the panels all across the top of the car

- Requirement:

- Notes:

Lamination

- Purpose:

- Requirement:

- Notes:

Power System

Power Supply

- Purpose:

- Requirement:

- Notes:

Spot Welder

- Purpose:

- Requirement:

- Notes:

Welcome to the University Wiki Service! Please use your IID (yourEID@eid.utexas.edu) when prompted for your email address during login or click here to enter your EID. If you are experiencing any issues loading content on pages, please try these steps to clear your browser cache.